Popular on s4story

- Super League (N A S D A Q: SLE) Enters Breakout Phase: New Partnerships, Zero Debt & $20 Million Growth Capital Position Company for 2026 Acceleration - 188

- New Book "Downsize With Dignity" Helps Missouri Families Navigate Senior Moves - 185

- Entering 2026 with Expanding Footprint, Strong Industry Tailwinds, and Anticipated Q3 Results: Off The Hook YS Inc. (N Y S E American: OTH) - 168

- Russellville Huntington Learning Center Expands Access to Literacy Support; Approved Provider Under Arkansas Department of Education - 165

- Writing a Memoir About His Hometown of Quincy Mass. Turned Into a Search for His Missing Father - 162

- Christy Sports donates $56K in new gear to SOS Outreach to help kids hit the slopes - 162

- Phinge CEO Ranked #1 Globally by Crunchbase for the Last Week, Will Be in Las Vegas Jan. 4-9, the Week of CES to Discuss Netverse & IPO Coming in 2026 - 127

- Private Keys Are a Single Point of Failure: Security Advisor Gideon Cohen Warns MPC Technology Is Now the Only Defense for Institutional Custody

- New Book Empowers Introverted Writers in a "Loud" Publishing World

- Compliance Is the Ticket to Entry: Legal Advisor Gabriela Moraes Analyzes RWA Securitization Paths Under Brazil's New Legislation

Similar on s4story

- Breakout Phase for Public Company: New Partnerships, Zero Debt, and $20 Million Growth Capital Position Company for 2026 Acceleration

- Japan's Patented "Hammock'n" Smartphone Band Targets Hand Fatigue From Long Phone Use

- Reditus Group Introduces A New Empirical Model for Early-Stage B2B Growth

- CCHR: Harvard Review Exposes Institutional Corruption in Global Mental Health

- Goatimus Launches Dynamic Context: AI Prompt Engineering Gets Smarter

- Lineus Medical Completes UK Registration for SafeBreak® Vascular

- Really Cool Music Releases Its Fourth Single - "So Many Lost Years"

- MGN Logistics Acquires Fast Service LLC, Fueling MyMGN Marketplace Expansion and Supercharging Expedited Coverage Nationwide

- Inkdnylon Launches Bilingual Ask Inkdnylon Platform

- FrostSkin Launches Kickstarter Campaign for Patent-Pending Instant-Chill Water Purification Bottle

Overlapping Bistable Dome Inventions Open New World Of Opportunities For AI and High Strength Sheet Metals

S For Story/10617953

Inventor says pairing overlapping bistable domes and artificial intelligence enables unique paper thin shape sensors, soft robots, and using thinner stronger metals to reduce vehicle weight and climate change.

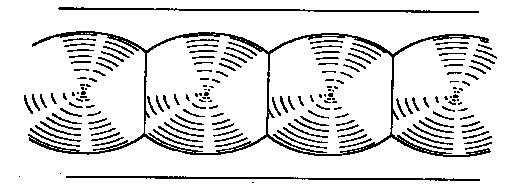

NEW YORK - s4story -- The website bistabledome.com describes using very shallow flex actuated overlapping bistable domes, or OBDs, to digitize, control, and utilize flexural forces in thin hard materials. Inventor Paul Ericson believes AI will enable development and commercialization of a wide range of unique OBD related products.

Ericson received two patents for using OBDs formed in thin 302 stainless steel to create a contact shape sensor and a pump that pumps when bent. The website explains how OBDs can also be used to stiffen and print shape high strength sheet metal.

The short video below shows behavior of equally bistable and unequally bistable overlapping domes. At end of video are two OBD pumps of different sizes.

http://youtu.be/ANtOyL9--9k

Overlapping bistable domes share flexural forces that switch individual bistable domes. OBDs are very shallow and in profile are usually no thicker than 3 times the original material. Rows and 2D arrays of OBDs form structures that are stiffer than the original metal.

"As long as flexural forces are not absorbed by the OBD material the structure can't be bent without forcing OBDs to the outside of the curvature," says Ericson.

Bend and shape sensors:

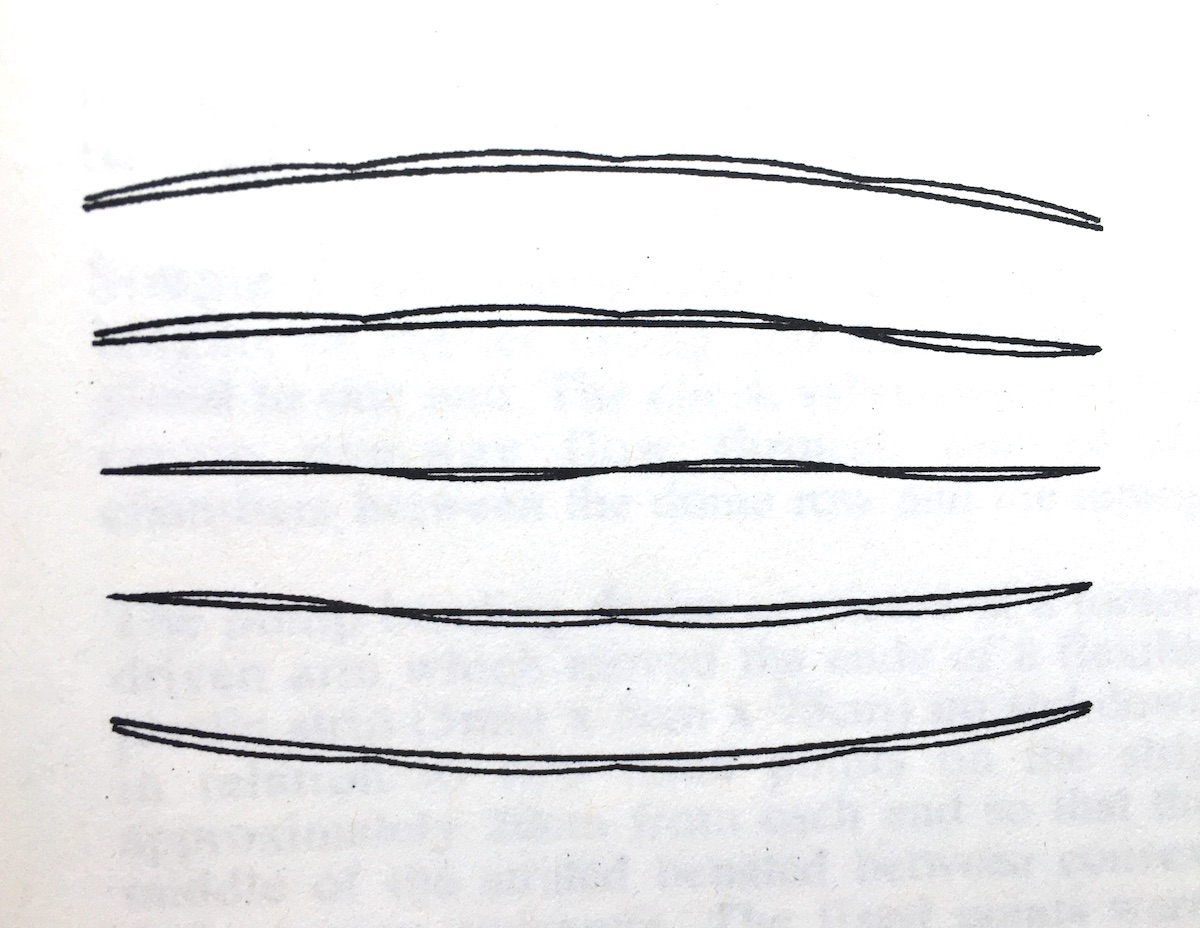

"OBD behavior is very predictable and small OBDs can be turned into on/off contact switches with paper thin flex circuitry. When included in a stiffer flexible material a single row of OBD switches becomes a bend or 2D shape sensor. The OBDs switch in numbers proportional to curvature and are capable of indicating where, how much, and in which direction from flat it is bent, regardless of its position in space. Multiple rows of OBDs can turn flexible surfaces into 3D shape sensors. They can be used for monitoring curvature, displacement, impact, force, motion, pressure, timing, position, weight, and fluid motion, for instance," says Ericson.

More on S For Story

A low resolution shape sensor prototype with 5 parallel rows of OBD switches is demonstrated at the bistabledome.com website.

Applications include softer, safer robots, smart safety bumpers, prosthetics, rehab and gait analysis tools, car seat sensors for triggering airbags, smart tires, athletic and sports training tools, and more.

"About 20 years ago a few car companies considered OBDs for seat sensors but there was no AI then," says Ericson.

AI makes OBDs more relevant and useful by enhancing pattern recognition for OBD switch behavior. Digital information from OBDs enables direct non-analog data processing, streamlining the integration of OBD shape sensing technology into applications and products. OBD sensors can help train and calibrate remote sensing and open possibilities where remote sensing is impractical or impossible.

Stiffening and shaping thin high strength steel:

Climate change is pushing the transportation industry to reduce weight. One problem is springback, which increases the unpredictability in stamping thin high strength metals. Springback can be worse for large radius curvatures common in transportation applications.

2D arrays of equally bistable OBDs can stabilize in a wide range of shapes and radii. OBDs with a bias for one side can be used to force flat materials into desired shapes, from simple tubing to multidimensional shape.

According to Ericson OBD stamping pressure is relatively low for such high strength materials because they are stamped incrementally starting at an edge and deformation is absorbed by neighboring OBDs. "It's more like folding than stamping," says Ericson, who claims low pressure requirements means common 3D printing materials can be used for tooling, speeding up prototyping and development.

Ericson believes an impact printer that can stamp OBDs of different characteristics, instead of letters, could produce a wide range of curvature and shape and reduce the need for expensive tooling and stamping. For large scale production OBD rollers could also be used to give shape to flat sheet materials. OBD structures are reconfigurable and can be produced and stored in a flattened form until pushed into preferred shape.

More on S For Story

Coatings can be used to lock OBD orientation as well as offer control of stiffness/flexibility and force response. "Laminates of OBD layers can be very strong for their weight and could help reduce structural framing for vehicles, boats, containers, etc.," says Ericson.

By integrating AI-powered OBDs into vehicle design auto manufacturers can optimize shape and weight distribution to improve fuel efficiency. The shape sensing capabilities of OBDs can allow for precise adjustments to vehicle structure.

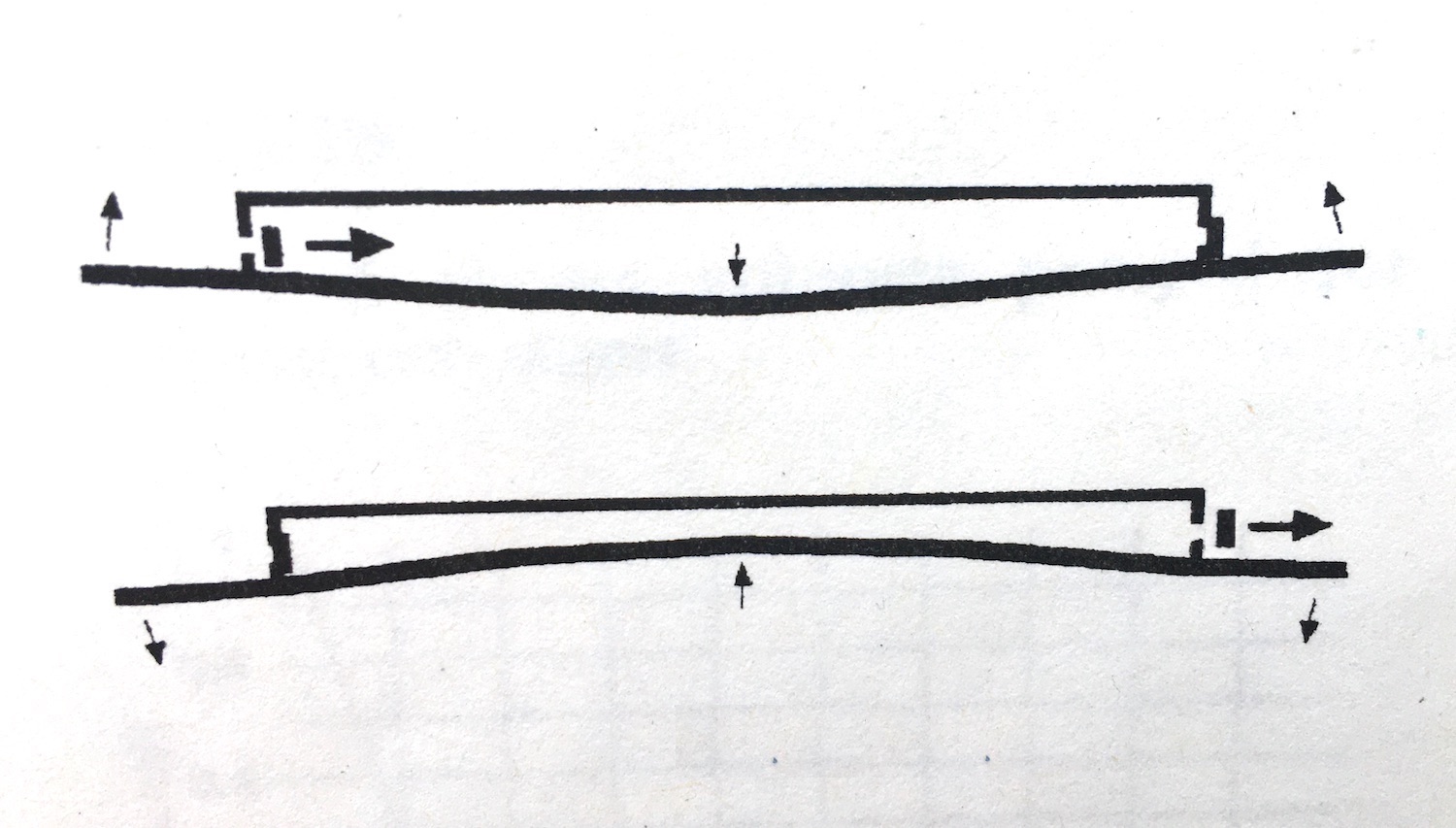

A pump that pumps when bent:

OBD pumps are very simple and made with a single OBD or a row of OBDs, a housing, and check valves. They can be made in a wide range of scale and utilize any natural or mechanical motion to pump. Large OBD pumps might be useful in utilizing wave or subsurface water motion to pump cooler water over corals, remove unwanted sediment, or pump materials for erosion control. Ericson suggests larger bistable dome pumps might be used for desalination.

Some of the ways artificial intelligence can help develop and enhance OBD applications include:

Pattern recognition: AI algorithms can be trained to recognize and correlate patterns of OBDs with specific shapes, radii, orientations, and other parameters.

Predictive modeling: AI can analyze OBD behavior and predict their response based on various factors. This can aid in designing more efficient and predictable OBD structures.

Optimization and simulation: AI algorithms can be used to optimize the arrangement and distribution of OBDs in arrays for specific applications. By simulating different configurations, AI can help identify the most effective layouts for printing shapes or strengthening thin hard metals.

Material research: AI can assist in exploring new materials or combinations to improve the performance of OBDs. By analyzing available data and conducting virtual experiments, AI can help identify materials with desired properties, such as flexibility, durability, and bistability.

Rapid prototyping: AI can facilitate the rapid design and prototyping of OBD-based structures. By generating and evaluating multiple design options, AI can help accelerate the development process and reduce the need for physical iterations.

Overall, AI can contribute significantly to the development of OBD technology by providing insights, automating processes, and enabling more efficient experimentation and optimization.

"The flex actuated bistable dome is a very simple structure but in overlapping interconnected rows and arrays it gets complicated. AI is the perfect partner for developing a wide range of unique OBD products and applications," says Ericson.

For more information visit bistabledome.com.

Ericson received two patents for using OBDs formed in thin 302 stainless steel to create a contact shape sensor and a pump that pumps when bent. The website explains how OBDs can also be used to stiffen and print shape high strength sheet metal.

The short video below shows behavior of equally bistable and unequally bistable overlapping domes. At end of video are two OBD pumps of different sizes.

http://youtu.be/ANtOyL9--9k

Overlapping bistable domes share flexural forces that switch individual bistable domes. OBDs are very shallow and in profile are usually no thicker than 3 times the original material. Rows and 2D arrays of OBDs form structures that are stiffer than the original metal.

"As long as flexural forces are not absorbed by the OBD material the structure can't be bent without forcing OBDs to the outside of the curvature," says Ericson.

Bend and shape sensors:

"OBD behavior is very predictable and small OBDs can be turned into on/off contact switches with paper thin flex circuitry. When included in a stiffer flexible material a single row of OBD switches becomes a bend or 2D shape sensor. The OBDs switch in numbers proportional to curvature and are capable of indicating where, how much, and in which direction from flat it is bent, regardless of its position in space. Multiple rows of OBDs can turn flexible surfaces into 3D shape sensors. They can be used for monitoring curvature, displacement, impact, force, motion, pressure, timing, position, weight, and fluid motion, for instance," says Ericson.

More on S For Story

- Japan's Patented "Hammock'n" Smartphone Band Targets Hand Fatigue From Long Phone Use

- Reditus Group Introduces A New Empirical Model for Early-Stage B2B Growth

- CCHR: Harvard Review Exposes Institutional Corruption in Global Mental Health

- Michelle Carey Launches "Creative Courage For Your Next Chapter" eBook for Busy Creators

- Adam Clermont Releases New Book Hong Kong Belongs to Hongkongers (香港係香港人嘅)

A low resolution shape sensor prototype with 5 parallel rows of OBD switches is demonstrated at the bistabledome.com website.

Applications include softer, safer robots, smart safety bumpers, prosthetics, rehab and gait analysis tools, car seat sensors for triggering airbags, smart tires, athletic and sports training tools, and more.

"About 20 years ago a few car companies considered OBDs for seat sensors but there was no AI then," says Ericson.

AI makes OBDs more relevant and useful by enhancing pattern recognition for OBD switch behavior. Digital information from OBDs enables direct non-analog data processing, streamlining the integration of OBD shape sensing technology into applications and products. OBD sensors can help train and calibrate remote sensing and open possibilities where remote sensing is impractical or impossible.

Stiffening and shaping thin high strength steel:

Climate change is pushing the transportation industry to reduce weight. One problem is springback, which increases the unpredictability in stamping thin high strength metals. Springback can be worse for large radius curvatures common in transportation applications.

2D arrays of equally bistable OBDs can stabilize in a wide range of shapes and radii. OBDs with a bias for one side can be used to force flat materials into desired shapes, from simple tubing to multidimensional shape.

According to Ericson OBD stamping pressure is relatively low for such high strength materials because they are stamped incrementally starting at an edge and deformation is absorbed by neighboring OBDs. "It's more like folding than stamping," says Ericson, who claims low pressure requirements means common 3D printing materials can be used for tooling, speeding up prototyping and development.

Ericson believes an impact printer that can stamp OBDs of different characteristics, instead of letters, could produce a wide range of curvature and shape and reduce the need for expensive tooling and stamping. For large scale production OBD rollers could also be used to give shape to flat sheet materials. OBD structures are reconfigurable and can be produced and stored in a flattened form until pushed into preferred shape.

More on S For Story

- Goatimus Launches Dynamic Context: AI Prompt Engineering Gets Smarter

- Global License Exclusive Secured for Emesyl OTC Nausea Relief, Expanding Multi-Product Growth Strategy for Caring Brands, Inc. (N A S D A Q: CABR)

- RNHA Affirms Support for President Trump as Nation Marks Historic Victory for Freedom

- WGN Chicago Features Shantel Love's Promote Your D@mn Self™ in Elevate Box Spotlight Segment

Coatings can be used to lock OBD orientation as well as offer control of stiffness/flexibility and force response. "Laminates of OBD layers can be very strong for their weight and could help reduce structural framing for vehicles, boats, containers, etc.," says Ericson.

By integrating AI-powered OBDs into vehicle design auto manufacturers can optimize shape and weight distribution to improve fuel efficiency. The shape sensing capabilities of OBDs can allow for precise adjustments to vehicle structure.

A pump that pumps when bent:

OBD pumps are very simple and made with a single OBD or a row of OBDs, a housing, and check valves. They can be made in a wide range of scale and utilize any natural or mechanical motion to pump. Large OBD pumps might be useful in utilizing wave or subsurface water motion to pump cooler water over corals, remove unwanted sediment, or pump materials for erosion control. Ericson suggests larger bistable dome pumps might be used for desalination.

Some of the ways artificial intelligence can help develop and enhance OBD applications include:

Pattern recognition: AI algorithms can be trained to recognize and correlate patterns of OBDs with specific shapes, radii, orientations, and other parameters.

Predictive modeling: AI can analyze OBD behavior and predict their response based on various factors. This can aid in designing more efficient and predictable OBD structures.

Optimization and simulation: AI algorithms can be used to optimize the arrangement and distribution of OBDs in arrays for specific applications. By simulating different configurations, AI can help identify the most effective layouts for printing shapes or strengthening thin hard metals.

Material research: AI can assist in exploring new materials or combinations to improve the performance of OBDs. By analyzing available data and conducting virtual experiments, AI can help identify materials with desired properties, such as flexibility, durability, and bistability.

Rapid prototyping: AI can facilitate the rapid design and prototyping of OBD-based structures. By generating and evaluating multiple design options, AI can help accelerate the development process and reduce the need for physical iterations.

Overall, AI can contribute significantly to the development of OBD technology by providing insights, automating processes, and enabling more efficient experimentation and optimization.

"The flex actuated bistable dome is a very simple structure but in overlapping interconnected rows and arrays it gets complicated. AI is the perfect partner for developing a wide range of unique OBD products and applications," says Ericson.

For more information visit bistabledome.com.

Source: Bistabledome.com

0 Comments

Latest on S For Story

- ANTOANETTA Partners With Zestacor Digital Marketing to Expand Online Presence for Handcrafted Luxury Jewelry

- Workforce AI Playbook Aligns with NIST AI Risk Framework, Advancing Responsible AI

- How Independent Publishers Are Rewriting the Future of Diverse Storytelling

- Digi 995 Launches as an Independent Digital Universe Powered by Community and Creator Vision

- FrostSkin Launches Kickstarter Campaign for Patent-Pending Instant-Chill Water Purification Bottle

- The New Monaco of the South (of Italy)

- New Biography Traces a Living Faith Journey from the South to the Bronx - One Woman's "Yes" That Shaped Generations

- Indies United is pleased to present our January 2026 book releases

- Lick Personal Oils Introduces the Ultimate Valentine's Day Gift Collection for Romantic, Thoughtful Gifting

- Erin Rosenblum, MFT Releases New Children's Picture Book Peanut Butter and Donner: Sweet Annie's Gr

- Thorn & Bloom Magazine Launches Fourth Issue, "Radical Joy We Cultivate," to Close the Year with Joy

- Lacy Hendricks Earns Prestigious MPM® Designation from NARPM®

- Jeekeshen Chinnappen Announces Upcoming Book

- Walmart $WMT and COSTCO.COM $COST Distribution as SonicShieldX™ Platform Sets the Stage for Accelerated Growth in 2026: AXIL Brands (N Y S E: AXIL)

- AI-Driven Drug Development with Publication of New Bioinformatics Whitepaper for BullFrog AI: $BFRG Strengthens Its Position in AI Drug Development

- IQSTEL Enters 2026 from a Position of Strength Following Transformational Year Marked by N A S D A Q Uplisting, Record Revenue and First-Ever

- Are You Hiring The Right Heater Repair Company in Philly?

- Appliance EMT Expands Professional Appliance Repair Services to Hartford, Connecticut

- Java Holdings LLC Acquires +Peptide, Expanding Portfolio Across Coffee, Science, and Functional Nutrition

- First Audiobook Wins Outstanding Creator Awards For Historical Fiction & Other Categories